What is the Greenhouse Challenge?

Recently, the “Deep Greens” team, comprised of Intel AI data scientists and horticultural experts from the Universidad Nacional Autónoma de México (UNAM), competed in, and won, a 24-hour hackathon for the chance to win one of 5 slots to grow cucumbers in an autonomous greenhouse later this year. The competition is to designed to test which team can grow the most cucumbers while reducing the number of total resources needed. By succeeding in the hackathon we now have the chance to test our deep reinforcement learning algorithms in a very novel environment. In this post, we will talk more about the overall challenge, our strategy for the hackathon, and the strategy going forward.

The competition is sponsored by the Wageningen University and Research (WUR) of the Netherlands, and the company Tencent*. The mission of this competition is to explore and stretch the boundaries of AI at the edge by applying Machine Learning (ML) techniques to crop yields with the lofty goal of creating an autonomous greenhouse.

Our team was fortunate to rely on the horticultural expertise from Professor Dr. Aarón I. Vélez Ramírez of UNAM and his students. Dr. Vélez studies environmental plant physiology and has experience with high-tech greenhouse production. This partnership has been invaluable, as Dr. Vélez and his students have a wealth of knowledge in the theory and practice of growing plants in a greenhouse.

Pre-challenge Hackathon—Automated mail clients and hyperparameter optimization

During the hackathon, our goal was to maximize the profit of a growing season by toggling about 200 parameters related to temperature, shading, cucumber spacing, and pruning strategy. These parameters were input into a greenhouse model which simulated a three-month cucumber growing season in roughly 1-2 minutes. Before we were even able to start toggling the parameters, one of our largest hurdles was instrumenting an email sender and listener. We were able to achieve this using a combination of Flask and sleep commands in Python. Although the use of an email client wasn’t optimal, we applaud the organizers for its use as it ensured that all teams could compete regardless of their technological expertise. The organizers provided the following schematic as an example of the full pre-challenge setup.

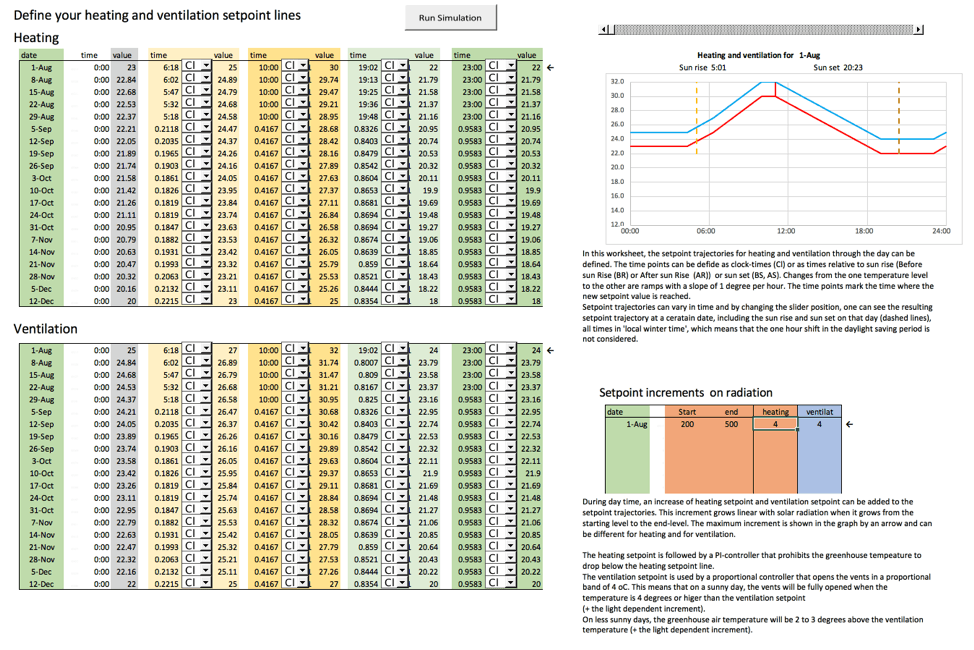

Once we created an automated email client, we began focusing in on optimizing the parameters. For instance, we could change the temperature strategy up to 20 different times over the course of a season as shown in the image below. Each temperature strategy runs for a certain number of days and consists of temperature and ventilation setpoints. The greenhouse will heat until a certain temperature is met, and then start to vent when a different temperature is exceeded. These setpoints could be changed over the course of a day. A spreadsheet provided by the organizers allowed us to see what our heating and ventilation setpoints would look like over the course of a day in relation to the sunrise and sunset.

In order to find the best parameters, we used a combination of hyperparameter search techniques and our horticultural experts at UNAM. To start, UNAM provided us with an initial search space, which we then used to kick off a number of automated runs. Because we were rate limited in this competition, we were unable to allow the algorithm to keep on trying different parameters, and potentially seek out the perfect combination of settings. Each team was only allowed to submit one proposal at a time, and the simulator took 1-2 minutes to run. All told, we were able to run about 300 different scenarios, far less than the number of runs necessary for 200 parameters.

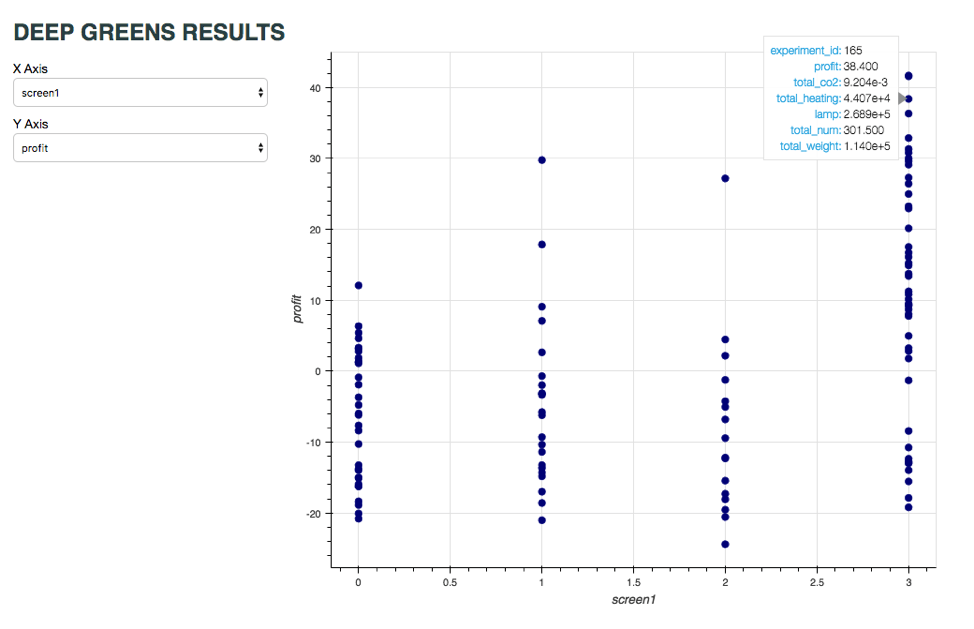

However, we were able to learn from the runs which helped guide us to a winning solution. While the automation ran, we viewed an interface which kept track of the experiment result, along with all hyperparameters for that run. Soon trends began to emerge. For instance, we noticed that the third screen option yielded higher profits on average compared to the other screen options. Our counterparts at UNAM were also looking at this information and told us how to change our search space. At the same time, they hand-designed runs that we interspersed with our automated runs. In this way, the automation was helping guide the experts, while in turn, the experts were helping to guide the automation.

Going forward—Deep Reinforcement Learning

We will be utilizing a fairly different strategy for the actual challenge beginning in late August. In the challenge, we will be trying to maximize the number of sellable cucumbers that are grown, while minimizing the operational cost that comes from lighting, heating, and human intervention. Between now and August 27th, when our cucumbers are planted, we will be developing deep reinforcement learning algorithms that will be able to dynamically respond to the current state of our greenhouse now that we have more time and more data.

The researchers at UNAM have developed a greenhouse model that achieves similar results to the model used by WUR during the pre-challenge hackathon. With this model, we can iterate faster, as well as receive intermediary status reports from the greenhouse such as crop health. These intermediary reports are necessary for reinforcement learning, as we will now be able to adjust our settings more rapidly. To optimize performance for our task, the team will use a Kubernetes* cluster to run our simulations, which has over 2,000 cores.

Additionally, the team will add sensors to the greenhouse in order to get additional information on plant health. We’ll be simulating the input of these sensors to the deep reinforcement learning algorithms, in order to determine which sensors will provide the highest value. Remember that these sensors consume power, space, and labor to install. Some of the sensors that we are investigating include the Intel® RealSense™ Depth Camera, Intel® Movidius™ Vision Processing Unit (VPU) for automatic crop health detection, crop temperature sensors, and near-infrared cameras to monitor the health of the crops at night.

Overall, we are quite excited for this next stage to see how well deep reinforcement learning can help grow crops in a controlled setting. The top 5 teams come from a wide range of academia and industry so it will be quite exciting to see who can produce the most cucumbers!

Notices and Disclaimers

Intel technologies’ features and benefits depend on system configuration and may require enabled hardware, software or service activation. Performance varies depending on system configuration. No computer system can be absolutely secure. Check with your system manufacturer or retailer or learn more at https://www.intel.com/xeon.

Intel, Xeon, Movidius, and Intel RealSense are trademarks of Intel Corporation or its subsidiaries in the U.S. and/or other countries

© Intel Corporation

*Other names and brands may be claimed as the property of others.

Mary is the Community Manager for this site. She likes to bike, and do college and career coaching for high school students in her spare time.

Mary is the Community Manager for this site. She likes to bike, and do college and career coaching for high school students in her spare time.

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.