- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

We have a problem in construction analysis on EN6337QA (lot S904FU1D, DC 1905 from Malaysia) .

There is multiple crack in inductance present in component.

Can you tell me why please ?

Link Copied

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello @PPuig ,

Could you please help to share the x-ray images that shows that the inductor inside the package is cracked?

I need that x-ray image for investigation, also how many parts has that issue?

Thanks,

Mostafa

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Mostafa,

We have made 3 CROSS-SECTION on 3 parts on this lot number S904FU1D, DC 1905 from Malaysia (Quantity buy 500)

Picture ''Package Cross-section''

Picture ''Crack1 and Crack2'' : Cross section A A'

Picture 'Crack3"" : Cros section B B'

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi @PPuig ,

Thanks a lot for sharing the cross section images.

Based on the images, that cracks looks like an airgap inside the ferrite material and i don't know how deep it is, but that crack (air gap ) will not effect the inductor functionality if it is already exist from the beginning where we test each part in production.

Could i know what is the issue you are facing with the part which makes you to do the cross section.

Thanks,

Mostafa

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Mostafa,

Air gap is between 5µm and 10µm.

is it normal to find Cracks on inductors before test?

i thinks this crack can evolve during lifetest, then induce instability or change the level of the exit of component.

Lot of inductor may be defective ?

Thanks,

Best regards,

Pascal

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Pascal,

Based on your cross-section images that cracks located inside the ferrite core and it is hard we can detect that inductors during the module assembly.

That inductor is a general used inductor and we didn't notice any core cracks during the module assembly inspections.

Based on the historical data, we don't have any issues related to the Inductor or any stability issues reported that caused by the inductor.

Based on the design rules, we take in consideration +/-25% marginal on the inductor variation.

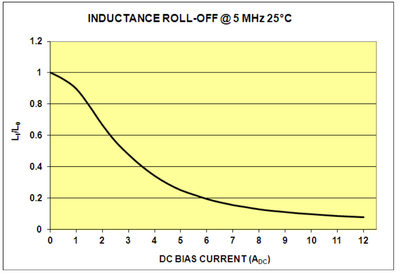

For EN6337_inductor, it is a soft saturated inductor which means the inductance drops with the current increases until saturation level.

Below is the normalized EN6337 inductor based on Enpirion inductor roll-off analysis.

So having any air gap inside the core, will not affect EN6337 stability where we take inductance variations over loading into consideration during the design.

The hard saturated inductors usually designed with air gaps to increase the saturation levels.

Since there is no any mechanical issues with the inductor construction, so we don't expect any failure caused by the air gap.

I would like to understand why you did the cross section analysis for the inductor and the die, so i could help you to fix the failure that happened to your design.

Also does there any chance that the crack caused by your cutting tools?

Regards,

Mostafa

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Mostafa,

Thanks for your answers.

i just want to clarify one point, these 3 components are not solder on PCB.

Normally, there is just one cross section on one component but after first result , we have cut 2 others component to eliminate our cutting tools.

We have made construction analysis because there is a hybride component (Die and other component in the same package) and it is necessary to have these data to make sure the component is conform for your equipement.

is it possible that lot number of component is defective ?

Can you check your tracability of this component (inductor) ? and make sure that lot number have not a problem?

Thanks

Best regards

Pascal

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Mostafa,

i think these cracks are not normal but Can you tell me if these Cracks are normal for Intel ?

Have you microsection to show us for others lot number please?

Thanks,

Best Regards

Pascal

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Pascal,

I have checked internally with the production team and they think this cracks happened inside the inductor core and close to the inductor turns due to the cutting machine. where they visually inspect the inductor before the assembly.

They didn't report any inductor cracks for any of our products before.

Enpirion modules use same packaging techniques with all the product and they didn't have any failure related to the inductor before.

So please let us know if you heard any mechanical noise from a mounted product when it was powered on where that mechanical noise probably comes from the inductor core vibration.

Regards,

Mostafa

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Printer Friendly Page