Applying advanced analytics to various aspects of the supply chain can provide significant business benefits, as illustrated by Intel’s experience:

- USD 25.4 billion in additional revenue and cost savings since 2009

- Average solve time of 1.3 minutes for each final analytics iteration, compared to hours or even weeks using manual processes

- Ability to evaluate 5–10 times more scenarios than before

As an integrated device manufacturer (IDM), Intel’s success depends heavily on maximizing revenue and minimizing cost across product design, manufacturing, and the supply chain network. From architecture design to materials routing, hundreds of thousands of decisions must be made based on massive amounts of supply chain data. Using advanced analytics, Intel can make faster, better, and more integrated decisions to optimize the use of manufacturing investments and better satisfy customer demand.

Challenge

With one of the world’s most complex supply chains, Intel manages six manufacturing stages at more than 200 internal and outsourced factories in 13 countries. Intel produces 400 unique wafer types and ships 600 million units per year. Optimally balancing demand, manufacturing process technology, product architecture, and supply chain routing is no mean feat.

Solution

Intel’s innovative advanced analytics capability spans product architecture design through supply chain planning. Customized optimization, AI, and machine-learning algorithms run on servers powered by Intel® Xeon® and Intel® Xeon® Scalable processors. Using decomposition and iteration, the analytics system can produce answers in a matter of minutes, giving planners the ability to make informed decisions that maximize Intel’s capital investments and providing a competitive advantage.

Results

Implementation of this capability over the majority of Intel’s product portfolio has increased annual revenue by an average of USD 1.9 billion and reduced annual costs by USD 1.5 billion. Total benefits of USD 25.4 billion have accrued since 2009. Further, supply chain planners can evaluate scenarios in mere minutes, enabling faster decision-making. Intel’s supply-chain planning excellence resulted in winning the 2020 INFORMS Edelman Award. This award is a global competition that recognizes and rewards outstanding examples of operations research, management science, and advanced analytics.

Optimizing a Complex Supply Chain Requires Advanced Analytics

Intel’s supply chain is exceedingly complex and sophisticated. For example, it includes 200+ facilities in 13 countries, nearly 20,000 suppliers, and thousands of customers. Intel’s new business growth has dramatically increased supply chain complexity. Today, Intel produces a total of 2.5 million wafers each year - 400 unique wafer types, which are part of 4,000 unique SKUs. Intel ships 600 million units per year and generates 1 TB of supply chain data every day. To optimally utilize manufacturing resources and meet customer demand, Intel must schedule every item, location, and route for each week over a one-year period. This involves 37.2 thousand planning items and 22.4 million routes. Performing such optimization manually would be humanly impossible.

Customized, Decomposed Algorithms Running on Intel® Hardware Solve Tough Problems

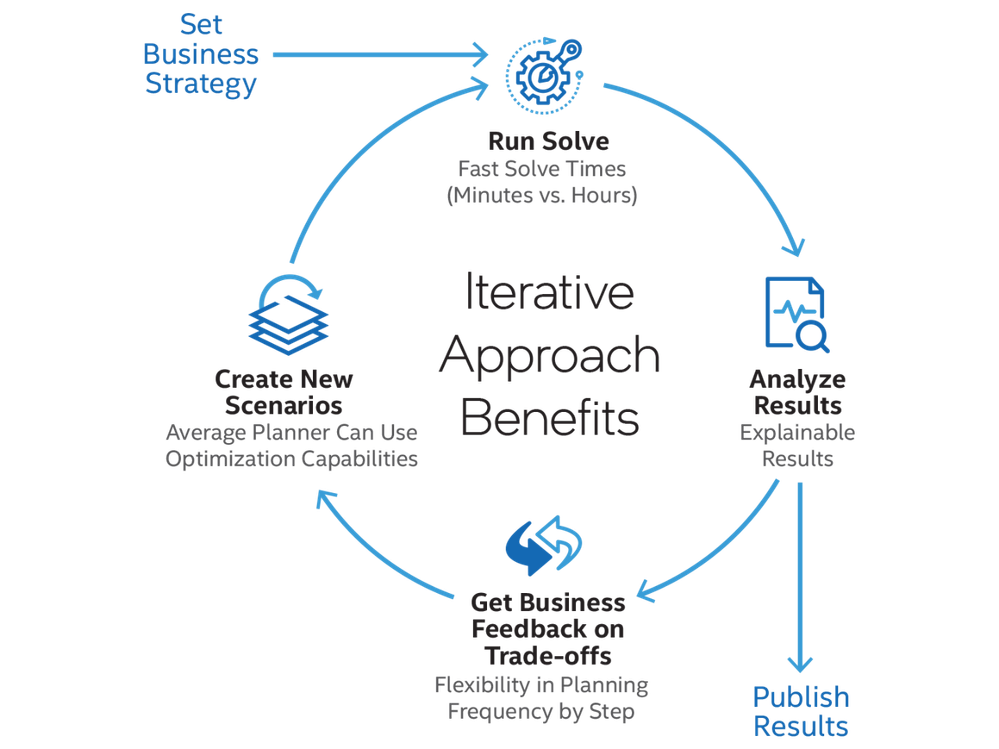

Delivering end-to-end advanced analytics to support product architecture design and supply chain planning requires a framework that is (1) easy to use, (2) flexible to support changing requirements, and (3) performant and scalable to meet the growing advanced analytics needs of the company. Intel’s analytics framework supports a broad range of product architecture design and supply-chain planning capabilities. The framework supports an iterative approach (see Figure 1) by combining many advanced techniques to solve separate aspects of the overall problem, such as product composition, wafer start optimization, network capacity alignment, and optimized routing. The framework is built as a composable enterprise system with mobile-first cloud visualization, robotic process automation, and big data management. It also features always-on high availability and failover clustering. A lambda architecture is used with an in-memory speed layer, a disk-based batch layer, and automated storage tiering using hot (in-memory), warm (on disk), and cold (Hadoop Distributed File System) storage. Microservices wrap the data tier and expose data to consuming clients for actionable insights and visualization and are hosted on load-balanced servers. The design of the framework helps ensure high throughput and low latency response times.

Figure 1. Intel uses a combination of advanced analytic techniques to decompose supply chain optimization into manageable chunks that enable fast, iterative analysis.

This solution provides a competitive advantage and is a foundational element of Intel’s supply-chain transformation effort.The solution framework uses on-premises private scale-out clusters for data locality and security requirements. Many analyses are currently being migrated to run on local Kubernetes clusters for maximum scalability. The various algorithms are implemented using a variety of languages and frameworks, depending on the specific business needs. The analytics clusters are powered by a combination of Intel® Xeon™ and Intel® Xeon™ Scalable processors and take advantage of libraries optimized for Intel® architecture, such as Intel® oneAPI Math Kernel Library (oneMKL). As Intel’s products become more complex with more features on smaller chips, Intel plans to explore hardware upgrades for its advanced analytics system, such as using the latest Intel Xeon Scalable processors featuring Intel® Deep Learning Boost and Intel® Advanced Vector Extensions 512.

More Revenue, Less Cost, Improved Efficiency, and Better Sustainability

Intel has realized financial, organizational, and environmental benefits from its supply-chain optimization efforts. From a purely financial point of view, advanced architecture design and supply chain analytics have increased annual revenue by an average of USD 1.9 billion and reduced annual costs by USD 1.5 billion, for a total benefit of USD 25.4 billion since 2009. From an organizational perspective, supply chain planners can now solve their problems in minutes or hours instead of days or weeks. Alternatively, they can evaluate 5–10 times more scenarios than before, which helps improve solution quality under different business conditions. And the benefits extend beyond Intel to the entire planet: the advanced analytics have optimized manufacturing processes, resulting in using 2.4 billion gallons less water and eliminating 0.5 billion gallons of wastewater over the last decade. Intel’s supply-chain transformation efforts using advanced analytics has attracted industry notice; Intel has been on Gartner’s Top 25 Supply Chain list for more than a decade and is the 2020 INFORMS Edelman Award winner.

Learn More

You may find the following presentation and paper useful:

2020 Franz Edelman Competition Presentation

Transforming Intel’s Supply Chain with Real Time Analytics

This story is brought to you by the SupplyChain@Intel

program. For details, contact your Intel representative.

Notices and Disclaimers

All information provided here is subject to change without notice. Contact your Intel representative to obtain the latest Intel product specifications and roadmaps. Intel technologies’ features and benefits depend on system configuration and may require enabled hardware, software, or service activation. Performance varies depending on system configuration. No computer system can be absolutely secure. Check with your system manufacturer or retailer, or learn more at intel.com.

The information provided in this paper is intended to be general in nature and is not specific guidance. Recommendations (including potential cost savings) are based on Intel’s experience and are estimates only. Intel does not guarantee or warrant others will obtain similar results. Information in this document is provided in connection with Intel products and services. Except as provided in Intel’s terms and conditions of sale for such products, Intel assumes no liability and Intel disclaims any express or implied warranty, relating to sale and/or use of Intel products and services, including liability or warranties relating to fitness for a particular purpose, merchantability, or infringement of any patent, copyright, or other intellectual property right.

No license (express or implied, by estoppel or otherwise) to any intellectual property rights is granted by this document. Copyright © Intel Corporation. All rights reserved. Intel, the Intel logo, and other Intel trademarks are trademarks of Intel Corporation or its subsidiaries. Other names and brands may be claimed as the property of others.

Mary is the Community Manager for this site. She likes to bike, and do college and career coaching for high school students in her spare time.

Mary is the Community Manager for this site. She likes to bike, and do college and career coaching for high school students in her spare time.

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.