- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi,

we use A10 GX(10AX057H3F34E2SG) , FBGA package 1152 pins.

Desinged ONE whole large heatsink mounted on the top of 3 pcs of A10. Power is 20 Watt for each one, and we use compressible thermal pad for interfacing material placed between case top of A10 and metal heatsink.

When mounting, we must add certain pressure to keep the thermal pad contact with IC surface tightly to ensure the good thermal conductivity.

So what is the recommended Mechanical Pressure for A10 BGA ? (unit is MPa or PSI ,Pounds per square inch ), or what is the pressure limit so as to keep IC from being destroyed by over stressed, as well as avoiding long term crack of BGA balls.

I think mechanical characteristic of this kind of BGA packages might be similar , independent of specific part number, but I not sure of this, because different manufacturer may have difference. So I hope Intel expert could give some suggestions. A similar device of Xilinx is recommend to use 20-40 psi pressure. Any comments are welcome.

For Intel, I found this link, but not sure where to confirm the material of our part is SnPb (tin-lead) balls or SAC (tin-silver-copper) . Also not sure whether this informationn applies to all Intel FPGA.

https://www.intel.com/content/www/us/en/programmable/support/support-resources/knowledge-base/solutions/rd04172001_4367.html

Thanks

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Yi Xiao,

Apologize that i share the wrong information. It should be SnAgCu. You may find the solder ball information at our package drawing.

https://www.intel.com/content/www/us/en/programmable/support/literature/lit-index/lit-pkg/package.html?family=Arria_10

Regards,

YL

Link Copied

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

up

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

uppp

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Yi Xiao,

Yes, you can apply the information to all Intel FPGA.

https://www.intel.com/content/www/us/en/programmable/support/support-resources/knowledge-base/solutions/rd04172001_4367.html

For your device, Arria 10 (10AX057H3F34E2SG), it is using FBGA package with SnPB Solder ball.

Regards,

YL

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi YL,

Where could we find the ball material information ?

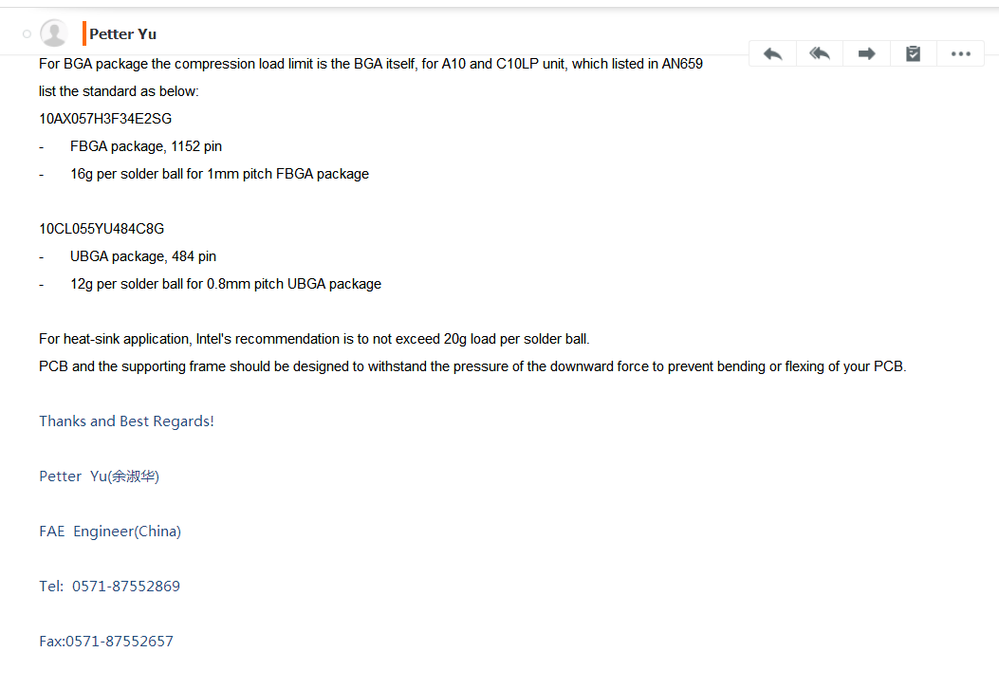

Loacal Intel support tell me A10 use SAC (tin-silver-copper) solder balls, which is different from your answer. I am CONFUSED and not sure who is correct. Below is the screenshot of their email.

We also use 10CL055YU484C8G, UBGA 484 pins, and need to know its ball material type.

By the way, I thought all intel device comply to ROHS, SnPb seems to contain Pb......

Thanks.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

up

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Yi Xiao,

Apologize that i share the wrong information. It should be SnAgCu. You may find the solder ball information at our package drawing.

https://www.intel.com/content/www/us/en/programmable/support/literature/lit-index/lit-pkg/package.html?family=Arria_10

Regards,

YL

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi, YL, coud you please help look on this question? Thanks.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Yi Xiao,

Apologize that i cannot help you in this question as i am not the expert in enpirion product. However, i will urge the owner of the thread to answer your enquiry as soon as possible.

Regards,

YL

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Printer Friendly Page